In today's fast-paced work environment, choosing the right equipment can make all the difference. But with a vast array of forklifts on the market, selecting the perfect one for your needs can feel overwhelming.

Are you struggling to decipher counterbalances from reach trucks, and pallet jacks from side loaders? One thing's for sure—you deserve reliable machinery that streamlines your operation instead of adding confusion.

Here at Sam's Mechanical Service, our years of experience in material handling solutions extend beyond skid steer and excavator attachments. In this blog post, we'll delve into the most popular forklift types, exploring their common uses, strengths, and weaknesses.

Get clarity on the various options and don't forget to check out our homepage for more top-notch equipment solutions to supercharge your productivity!

Counterbalance Forklifts

The workhorse of the material handling world, the counterbalance forklift reigns supreme for its versatility and functionality. This classic design features forks in the front for grabbing and lifting loads, balanced by a counterweight in the rear to ensure stability. Counterbalance forklifts are prevalent in warehouses, tackling tasks like transporting goods, loading and unloading trucks, and stacking pallets. Their user-friendly design and strong lifting capacities make them a popular choice.

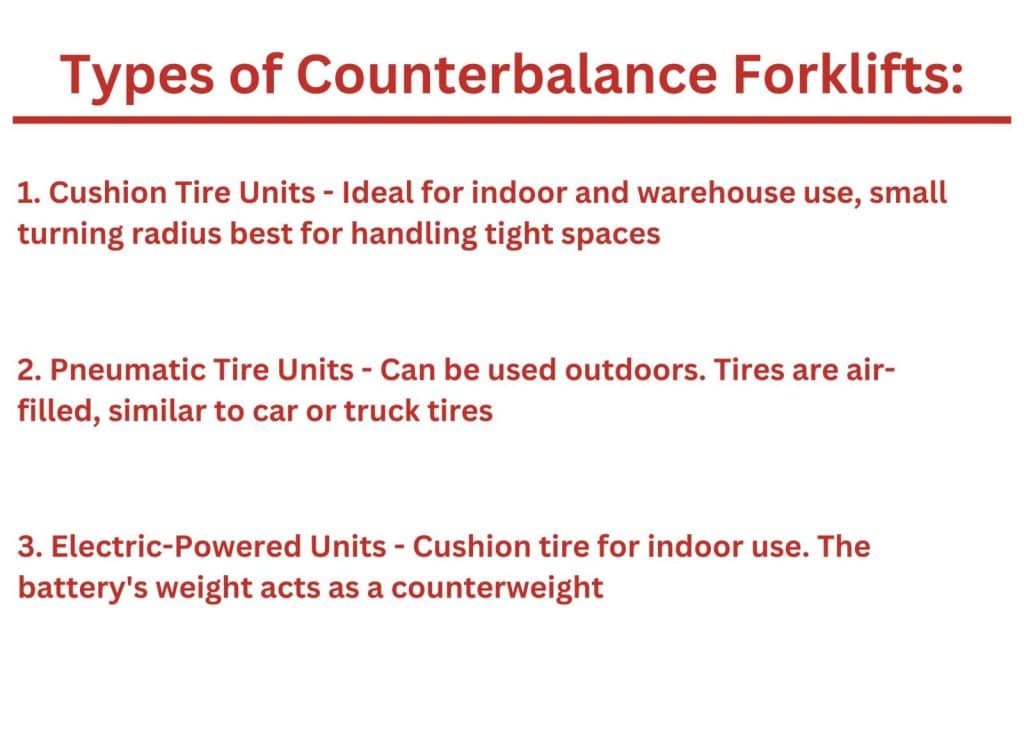

Keep in mind that safe operation requires proper training due to the forklift's weight and potential for tipping. Additionally, their size can limit maneuverability in tight working environments. To accommodate specific needs and environments, there is a wide array of counterbalance lifts, such as:

- Cushion tire units: Great for indoor and warehouse use, cushion tires are designed for use on smooth surfaces, such as a warehouse's concrete floor. These forklifts are optimized for handling tight spaces and have a small turning radius.

- Pneumatic tire units: Similar to cushion tire units, pneumatic tire units are more like car or truck tires and filled with air like traditional tires. They can be used indoors or outdoors.

- Electric-powered units: Designed to run on electric power, the battery's weight acts as a counterweight to the load being moved. Electric units usually have cushion tires.

All in all, counterbalance forklifts offer longer lifespans, increased versatility, and a safer way to carry heavy loads.

Reach Fork Trucks

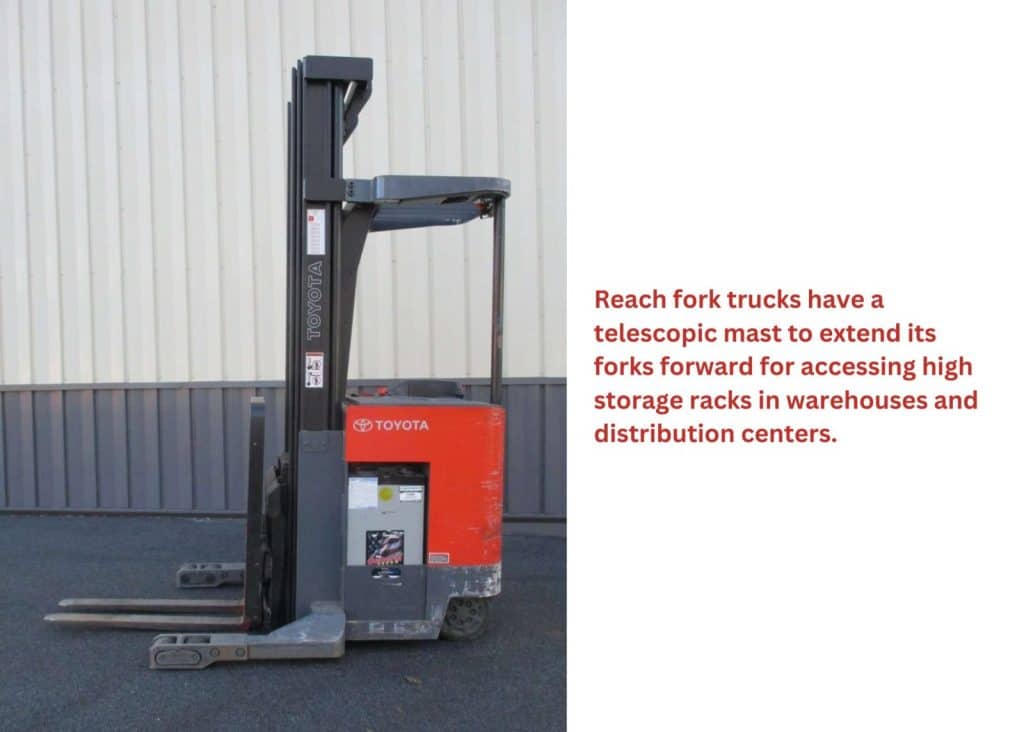

When it comes to maximizing warehouse space and conquering towering shelves, reach trucks are the undisputed champions. Unlike their counterbalance cousins, reach trucks boast a telescopic mast that extends the forks forward, allowing for exceptional reach heights.

This design makes them perfect for navigating narrow aisles and accessing high storage racks in warehouses and distribution centers. Similarly, their compact size and nimble steering provide excellent maneuverability in tight spaces. This, along with forklift extensions, allows warehouse operators to optimize storage capacity.

It is important, however, to remember that reach trucks are primarily designed for indoor use on smooth, even surfaces. Furthermore, because they are designed primarily for reach, they have limited load capacity compared to counterbalance forklifts.

Pallet Jacks and Trucks

The unsung heroes of short-distance material handling, pallet jacks and trucks offer a simple and budget-friendly solution. These compact go-getters are ideal for maneuvering pallets within warehouses, retail stores, or even loading docks. They come in two main varieties: manual and electric.

Manual pallet jacks require the operator to exert physical effort to move the pallet, making them a cost-effective option for occasional use or light loads. Electric pallet jacks, on the other hand, offer motorized assistance for effortless movement, ideal for frequent use or heavier pallets.

While both options are user-friendly and affordable, their limitations lie in lift height and overall capacity.

Are there any downsides to pallet jacks?

Simply put, they are designed for short-distance travel although can have a lifting capacity of over 5000lbs, are unsuitable for stacking pallets or highly repetitive loads requiring multiple trips/

For more on efficient material handling, check out our guide on pallet racking systems.

Side Loader Forklifts

Side loader forklifts are the ultimate specialists for conquering narrow aisles and maneuvering long, bulky materials.

Unlike their conventional counterparts, these forklifts have forks mounted on the side of the carriage, allowing them to operate efficiently in tight spaces. This unique design makes them perfect for applications like lumber yards, steel mills, or pipe distribution centers, where long objects need to be transported and stacked.

Side loaders excel in maneuvering in confined areas and handling cumbersome loads with ease. However, their strength in narrow aisles comes at the expense of general maneuverability. These forklifts are less versatile for open-area tasks and require an understanding of how to drive them, which is crucial to operating the equipment safely and not damaging the machine.

Combilift makes popular side-loader forklifts that can drive both forward and reverse and side to side.

Rough Terrain Forklifts

Rough terrain forklifts allow you to brave the elements and conquer uneven terrain. Built with rugged construction and powerful engines, these workhorses are designed to handle the demanding conditions of construction sites, lumberyards, and agricultural operations. Rough terrain lifts tend to be 4-wheel drive, which differs from most forklifts' typical rear-wheel drive.

Their large, knobby tires provide exceptional traction on rough surfaces, mud, and even loose gravel, ensuring stability and maneuverability when typical forklifts falter. This means increased productivity and efficiency in challenging outdoor environments.

However, the trade-off for this off-road prowess lies in cost and versatility. These forklifts typically come with a higher price tag compared to their indoor counterparts. Furthermore, their large tires and suspension systems can make them less comfortable and maneuverable on smooth, paved surfaces.

Telescopic Handlers (Telehandlers)

Telehandlers are the ultimate chameleons of the forklift world. They combine exceptional reach with impressive versatility. These machines boast a telescopic boom that extends outwards and upwards, allowing them to access heights unmatched by standard forklifts. This makes them invaluable in construction for placing materials on high scaffolding or loading trucks.

When it comes to agriculture, telehandlers can tackle tasks like lifting hay bales or feeding machinery. Logistics companies also utilize them for their ability to reach containers and unload heavy equipment.

But this adaptability comes at a price. Telehandlers are generally more expensive to purchase and maintain compared to other forklifts. Their complex design also necessitates specialized training for safe operation.

Important Features to Consider

When it comes to selecting a forklift, there are a few crucial features to consider. The first, and arguably the most important, is load capacity.

Load Capacity

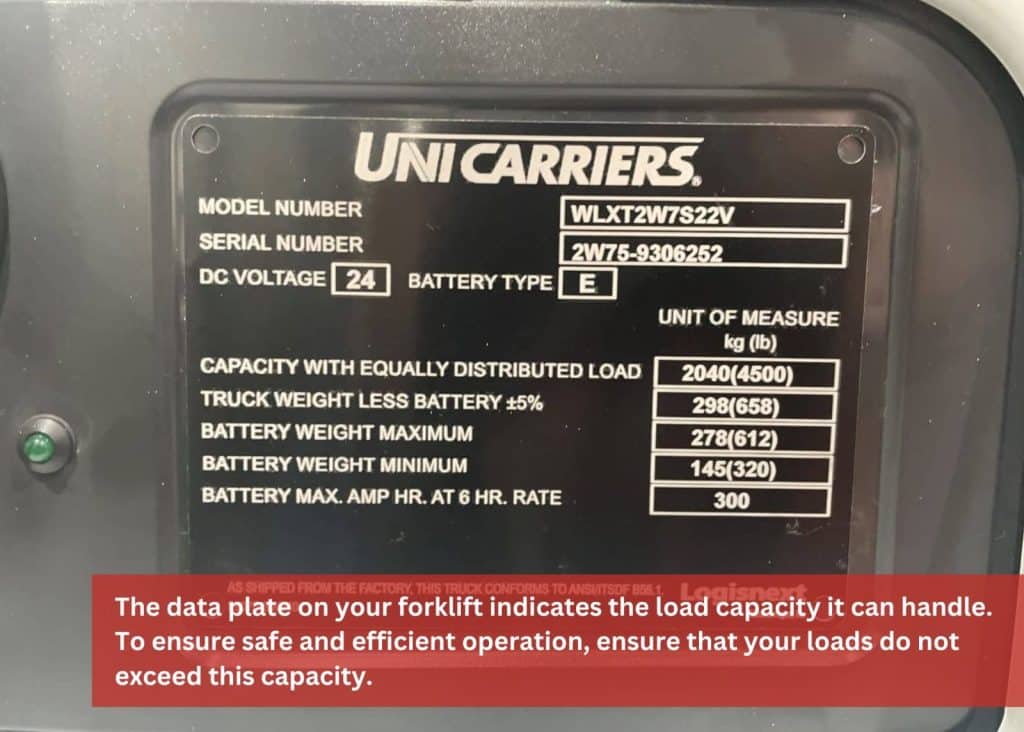

Load capacity refers to the maximum weight a forklift can safely lift and maneuver at a specific distance. Exceeding this limit can lead to tipping hazards, property damage, and even serious injury.

All forklifts have a data plate that indicates their load capacity, model and serial number, fuel, and other pertinent information.

To guarantee a safe and efficient operation, it is crucial that you match the forklift's load capacity to your heaviest, regularly lifted loads. Don't forget to factor in additional weight from attachments you might use.

Here at Sam's Mechanical Service, we understand the importance of proper equipment selection. We can guide you toward a forklift with the ideal load capacity to handle your toughest jobs safely and efficiently.

Lift Height

Another crucial factor to consider when navigating the forklift selection process is lift height, which reflects the maximum height the forks can reach when fully extended. For instance, warehouse managers will prioritize having a forklift with a lift height that accommodates their highest storage racks.

Selecting a forklift with insufficient lift height can hinder productivity and force you to employ unsafe practices to reach elevated items. By carefully assessing your operational needs, particularly in terms of stacking and retrieval heights, you can guarantee a forklift that optimizes efficiency and prioritizes safety.

It’s also important to get the height measurements of where you plan to use your lift, particularly the doorways in your facility. Many a forklift dealer has had the experience of a customer buying a lift only to call back because they cannot fit the truck where they want to use it. They either have to exchange the unit, or the dealer ends up going out and removing the mast, moving the truck in, and re-installing it!

Fuel Type

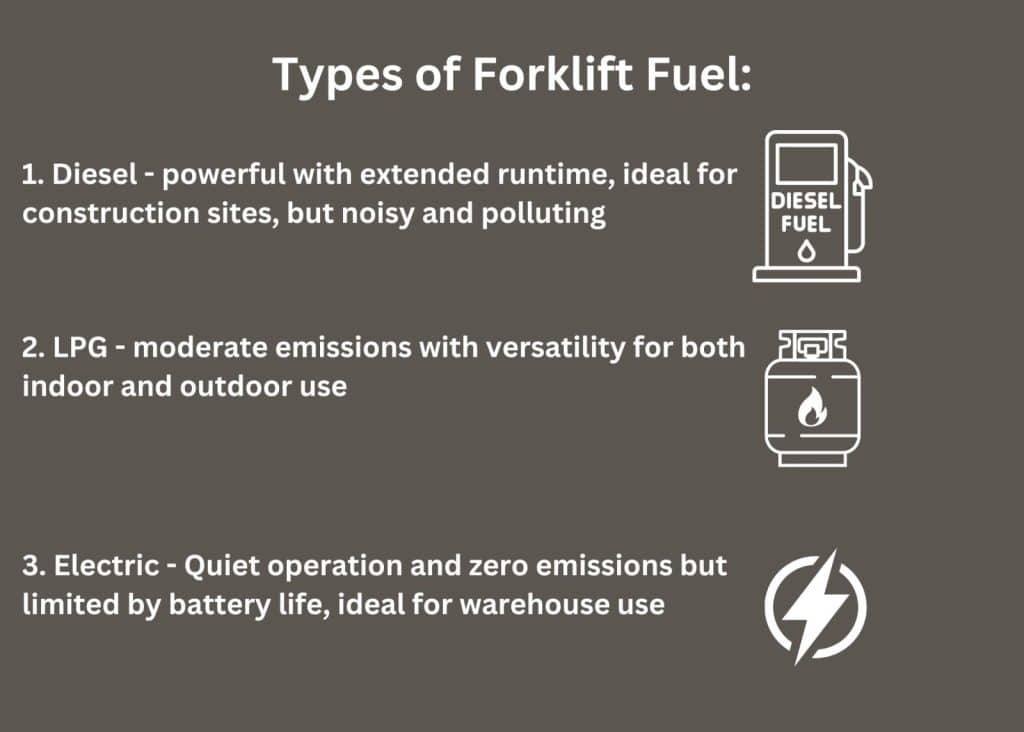

Forklifts come in various fuel types. Choosing the right fuel source optimizes performance and cost efficiency.

Electric forklifts reign supreme indoors, offering quiet operation and zero emissions, making them ideal for warehouses and other controlled environments. However, their range is limited by battery life.

Diesel forklifts are outdoor warriors, boasting power and extended runtime, perfect for construction sites or lumberyards. The drawback? They can be noisy and emit pollutants.

LPG (liquefied petroleum gas) forklifts offer a middle ground, providing versatility for both indoor and outdoor use with moderate emissions.

The ideal fuel type hinges on your operational environment. Electric forklifts might be perfect for a clean warehouse, while a diesel option might be better suited for a dusty construction site. Considering both performance and cost implications, like refueling infrastructure or electricity needs, is crucial.

Maneuverability

Maneuverability is the magic ingredient for maximizing productivity in tight spaces. This factor significantly impacts how efficiently your forklift navigates warehouses, retail stores, or any area with limited room.

Two key elements influencing maneuverability are aisle width and the forklift's size and turning radius. Narrow warehouse aisles call for a forklift with a compact design and a tight turning radius to ensure smooth operation without sacrificing efficiency. Conversely, larger, open spaces might allow for a bulkier forklift with a wider turning radius.

When choosing a forklift, ensure that it is designed to steer with the rear tires, allowing for tighter turning radii. The vast majority of forklifts are designed this way, but it’s always a good idea to double-check!

By carefully assessing your workspace, particularly aisle width and the need for sharp turns, you can select a forklift that optimizes maneuverability and keeps your operation running smoothly.

Choosing the Perfect Forklift for Your Needs

We've explored the diverse landscape of forklifts, each boasting strengths and weaknesses tailored for specific tasks. From the workhorse counterbalance forklift to the space-saving reach truck, the ideal choice depends on your operational environment and material handling needs. Remember, critical features like load capacity, lift height, fuel type, and maneuverability significantly impact performance and safety.

Here at Sam's Mechanical Service, our expertise extends to helping you select the perfect forklift for your operation. Whether you require the muscle of a rough terrain forklift or the precision of a telehandler, we offer a variety of solutions to ensure top-notch performance for all your material handling needs.

Don't let navigating the world of forklifts slow you down. Visit our website today and explore the extensive range of forklifts and rentals we offer. With Sam's Mechanical Service as your partner, you can unlock new levels of productivity and conquer any material handling challenge that comes your way!